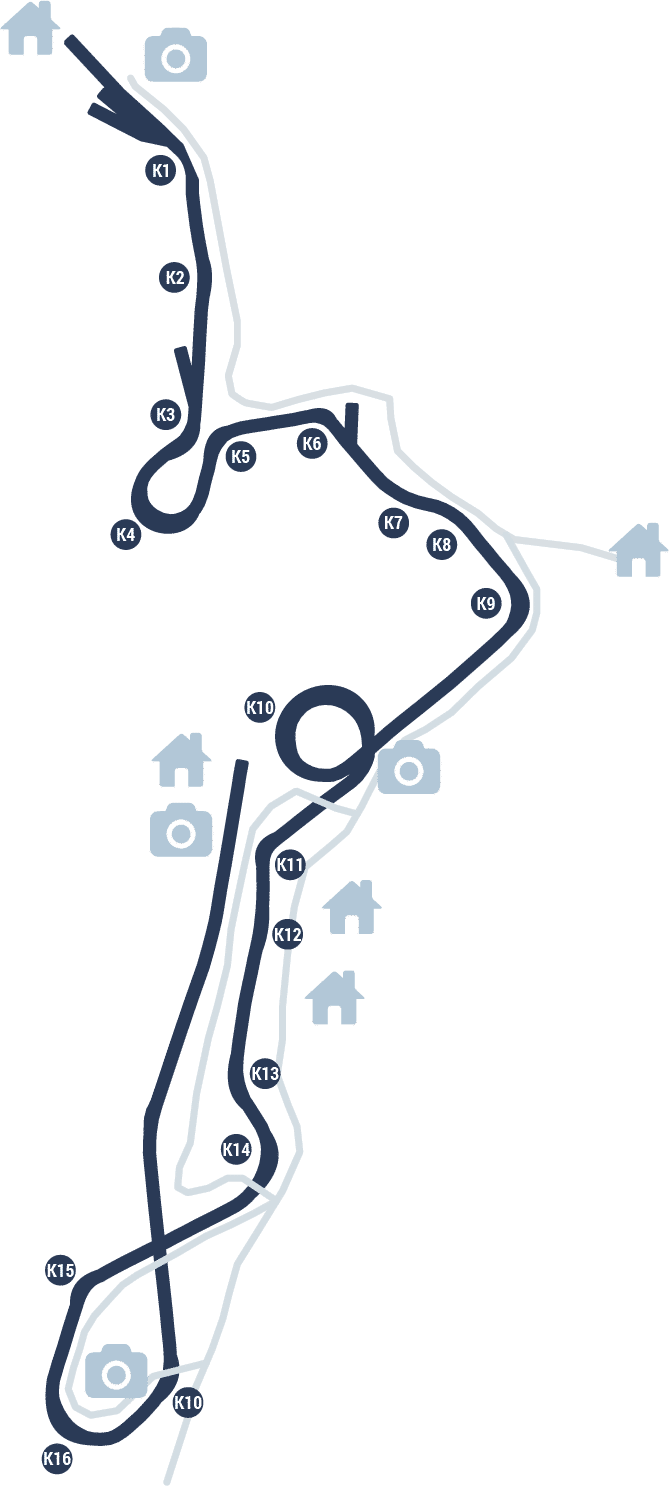

Track profile

Start

Luge Women

Start Grandstand

Photo Hotspot

Start area

Bob, Skeleton

& Luge Men

The Omega

Curve 4

Start Area

Luge two men & Guest Bob

Main entrance

Gate B / Bornweg

Roundabout

Photo Hotspot

Catering

Finish area

Award Ceremonies

Grandstand & Panorama Building

Target gyro

Photo Hotspot

Official timing

Brake slope

Press

Facts

Speed

- 140 km/h maximum

Number of curves

- 17 Bob / Skeleton / Toboggan Men's

- 15 Toboggan Women

- 11 Toboggan double seater / guest bob

- 7 Left curves

- 10 Right curves

Altitude

- 122.22m difference in altitude

- 15 maximum gradient

- 8.66 average gradient

- up to 140km/h Speed

Measuring Lengths - Start - Target

- 1413m Bob / Skeleton

- 1387m Toboggan Men's

- 1220m Toboggan Women's

- 996m Toboggan double seater

Timekeeping - Intermediate (Bob and Skeleton)

- 50m start time

- 387.50m 1. Intermediate period

- 641.50m 2. Intermediate period

- 891.50m 3. Intermediate period

- 1132,10m 4th Intermediate period

- 1410.90m End time

Virtueller Rundgang

360° Grad Erlebnis-Panorama

Erleben Sie die Bobbahn Altenberg im 360° Rundgang. (2018)

WHERE DOES THE COLD IN THE EISKANAL COME FROM

The refrigeration machine house behind the target gyro is the heart of the entire refrigeration technology. From here, a 30 km long pipe network runs through the entire concrete canal up to the bobstart. Around 45 tonnes of liquid ammonia are converted into gas by three compressors with an output of 250 kW each and sent through the pipe power system. The concrete can be cooled to -13°C. Along the railway there are 56 control points that measure the temperature of concrete and ice. Particularly attentive visitors recognize the holes with temperature sensors on the inner bands of the track. Depending on the weather conditions, a computer-aided process control system collects the (cold) data and automatically regulates the transport of refrigerant to the appropriate locations in fixed temperature ranges. In case of special requirements, refrigeration technicians and the ice master can also manually regulate the refrigeration system and particularly cool special web areas or even switch off the cooling in case of natural frost. In theory, the Altenberg racing sled and bobsleigh track could be iced up to plus 20°C outside temperature. This depends on wind and solar radiation, but causes an enormous energy and water consumption. By comparison, the performance of the refrigeration machines is roughly the same as that of 12,000 refrigerators.

PROCESS CONTROL SYSTEM

In order to ensure that this system has optimum safety and efficiency, a computer-controlled process control system has been installed, which, depending on the weather conditions, collects the data and transports refrigerant to the respective location of the railway (there are 50 so-called control points on the railway). Of course, the experiences of our ice master can be entered in this system. The system runs completely automatically, in case of malfunctions, the relevant service members are informed by telephone dialer and mobile phone.

INSIGHT INTO MEASUREMENT TECHNOLOGY

As the name suggests, the measuring technique has as its task to accurately record the times of individual athletes or sleds and bobsleighs. In addition, the coordination of the process in training and competitions is another important task. In coordination with the railway manager and the railway workers, competition and training trips are planned from start to finish.

It is also the interface for press, radio and television as well as the race management, jury and the organizing committee. The measuring technology is located in the target house. Equipped with 39 cameras, the measuring technology staff can view and monitor every single section of the railway.

For competitions and training trips, the employees in the measuring technology pass through information about loudspeakers to athletes and trainers as well as the railway workers, such as sweeping and curing times. Furthermore, the measuring technology is also responsible for the safety of athletes and railway workers. The track is only released to the athlete by the measuring technology when there are no more people in the track. The athlete is not allowed to start until he hears his name, the start signal (a beep) and the spoken "The Track is clear now" by the measuring technology employee and sees the green traffic light on. Thus, twice acoustically and visually at the start, when the track is released and the athlete is allowed to start. Once the start has been made and the first light barrier has been torn, another acoustic signal sounds on the entire track, so that everyone at the track knows, now the athlete is in the ENSO ice channel. In addition, the starting time of the travelling athlete is announced. In the case of falls, first aid or other rescue measures are coordinated by the measuring technology.

Through two independent time measuring systems (24 installed measuring stations), the employees in the measuring technology have documented all start, intermediate and end times and pass them on to trainers and officials. By analysing the times, trainers can evaluate the strengths and weaknesses of the individual athletes in detail.

In national and international competitions, the measuring technology also functions as a moderation office and information interface for visitors to the ENSO ice channel.

Information about the current race with anecdotes of the athletes is transmitted to visitors via the loudspeakers. Thus, the employee in the measurement technology must also be well versed in the sporting aspects.

Icing

In October, the bobsleigh track will begin to be closed. On average, about 8 ice workers spend a week icing the ice snake from the finish to the bobsleigh start. For this purpose, the concrete body is cooled down to approx. -13°C and applied by means of a fine water jet mm for mm ice and all this in pure manual work. The bobsleigh track is then "ready for use" if the ice has a thickness of approx. 2-6 cm (straight less, curves slightly more).